Strategie &

Organisation

Planung &

Realisierung

Optimierung &

Tuning

Logistics IT

Recent articles

Testimonials

References

National multichannel warehouse

State-of-the-art technology for flat and hanging goods

Customer: Retail industry

- Dramatic reduction of number of warehouse facilities and administrative complexity

- Increased inventory turnover via a single inventory pool for branches and eCommerce

- Shop floor readiness (e.g. using matrix sorting)

- Improved management efficiency for seasonal product lines

New warehouse creates room for expansion

Designed for growth

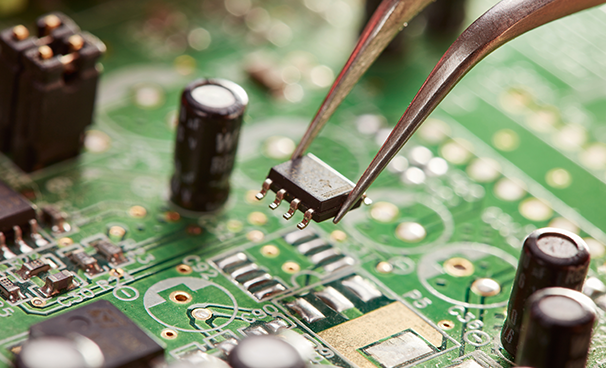

Customer: Electronics manufacturer

- Flexible and scalable warehouse concept

- Two expansion stages: 2018 and 2023

- Customer-oriented delivery of prototypes

- Ergonomic and flexible workstations

- Flexible allocation of spaces in shuttle

- MHE Invest: 12 million Euro, assortment: 36,000 SKU, shipments: 3,000 per day, positions: 9,000 per day