Satisfied customers speak for themselves!

References

Focusing on our customer’s success we have been working for over 20 years in consulting and implementation. Together with our customers, we design tailor-made intralogistics solutions that are economical, flexible, scalable, and guarantee them a secure investment for the future.

National multichannel warehouse

State-of-the-art technology for flat and hanging goods

Customer: Retail industry

- Dramatic reduction of number of warehouse facilities and administrative complexity

- Increased inventory turnover via a single inventory pool for branches and eCommerce

- Shop floor readiness (e.g. using matrix sorting)

- Improved management efficiency for seasonal product lines

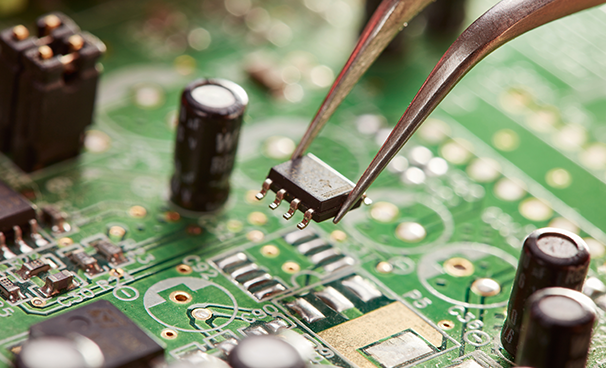

New warehouse creates room for expansion

Designed for growth

Customer: Electronics manufacturer

- Flexible and scalable warehouse concept

- Two expansion stages: 2018 and 2023

- Customer-oriented delivery of prototypes

- Ergonomic and flexible workstations

- Flexible allocation of spaces in shuttle

- MHE Invest: 12 million Euro, assortment: 36,000 SKU, shipments: 3,000 per day, positions: 9,000 per day

3A Warehouse audit

Modernization of warehouse processing

Customer: Mechanical Engineering

- Selection and assessment of suitable picking systems (pick-by-light, pick-by-beam, pick-by-scan)

- Hedging of investment decision

- Reduction of order throughput time

- Higher service level with later cut-off time

- Increased pick productivity

- Significant error reduction

Selection and design of new WMS

Reduce default risk

Customer: PBS/Chemical

- Integration of individual employee expertise

- Standardization of core processes

- Reduction of default risk

- Depiction of diverse requirements of commercial customers

- Creation of overview of requirements for hazardous substances

- Simplified process for the use of temporary employees

Expansion of B2C pharmaceutical warehouse

Focused on continuous growth

Customer: Pharmaceuticals / Health Care

- Creative & innovative processes

- Growing into automation

- Expansion in stages

- 100% control as a quality requirement

- Productivity increase

Central warehouse on green-field site

Restructuring of intralogistics

Customer: Wholesale electronics

- Growing into automation through planned open areas

- Storage and handling of various special containers

- Flexible storage capacity in accordance with future needs

- Ergonomic process design thanks to appropriate warehouse and materials handling systems

- Processing time reduced by 20%

Logistics concept with service focus

Focus on customer service

Customer: Dealer for assembly and mounting materials

- Improved delivery performance due to new service-oriented management

- Additional packing area for increasing capacities for large-scale orders

- Electronically supported packaging processes

- Ergonomic workstations

- Implementation during regular operations

- New packing area for large orders: MHE Invest: > 3 million euros, consignments: 400 per day, pick positions: 30,000 per day